Drums: The Circular Solution

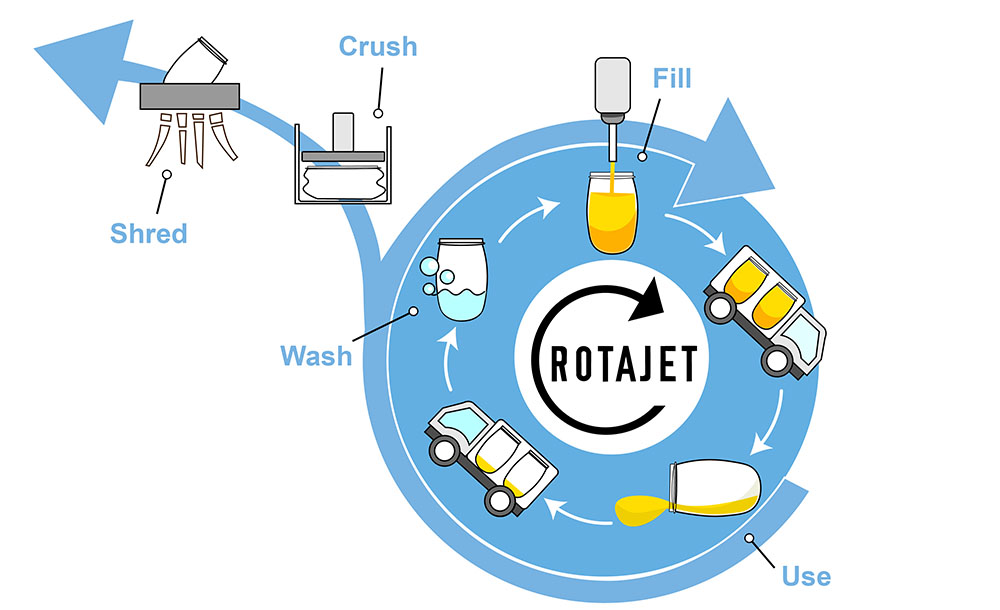

At Rotajet we believe that the key to building a circular economy is to create solutions to make doing the right thing, the cost-effective thing. We look after your processes across the lifecycle of your container, putting you in control, removing unnecessary costs and, automating time consuming manual processes.

For too long our clients have had to pay extraordinary fees for disposing of their drums or, transportation costs to send them out to be laundered externally. Now with Rotajet, you can install a circular system and reduce your carbon footprint as well as your monthly outgoings.

Whether you are a distributor or a manufacturer, end user or waste management company, we have flexible solutions to match your needs.

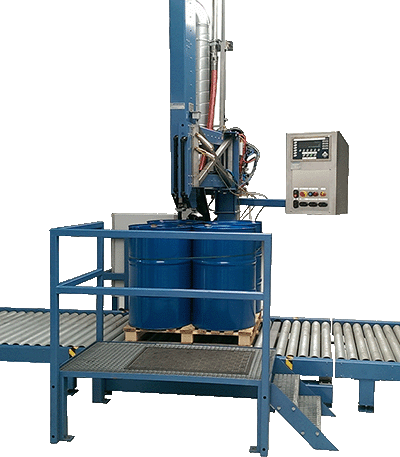

We are the UK agents for Gemini Techniek, a specialist manufacturer of ATEX and non-ATEX filling equipment.

Gemini have a full range of automatic and semi-automatic systems for filling drums with a full range of substances. customisable doses for and impingement , you are completely in charge of your filling operation.

Easily installed as an additional extra to any Rotajet drum reconditioning facility, providing a full circular solution to your use of HDPE or steel drums.

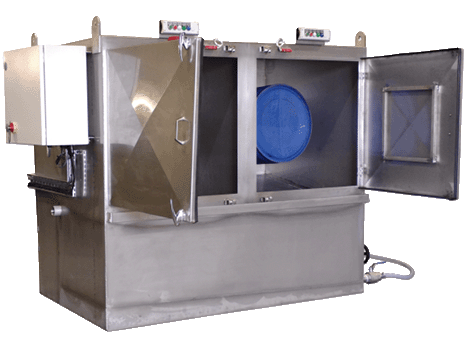

Solutions suitable for every application, we offer a full range of drum washers in the DW series. These machines range from single position, straight to waste machines up to multi-position recirculating systems.

With 30 years in the washing business, our team have the experience to tell you what chemicals, temperatures, dosing levels and cycle times you should expect from your application.

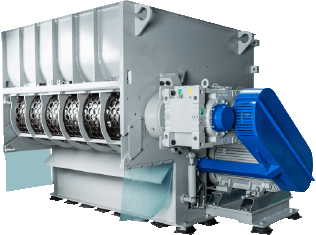

Over time, containers will be damaged due to wear and tear. It is important to safely disposing of the container, without leaving contamination inside that could be hazardous.

Rotajet have developed the CLEAN-N-CRUSH, a machine that will wash and crush the drum in one simple cycle. This ensures safety of the operator and allows easier handling and space saving of the drum to be then recycled or disposed.

With our partners in Germany, AMIS, we provide our expertise to deliver, install and service the suitable size reduction machinery.

This step allows the plastic material to be then fully recycled through extrusion, or prepares the material for resale.

Rotajet supply a full range of pressure testers for checking the integrity and to testing for any leaks in the container prior to any liquids being filled.

Faulty containers can be a huge hazard as tiny punctures or cracks can lead to the container leaking. Not only is this a loss in stock but also a huge health and safety issue, particularly if the liquid is in any way hazardous to human health or the environment.

We see quite often customers finding themselves in a huge logistical and financial nightmare as without an effective system, spent containers build up on site in need to be processed. These spent containers now need to be disposed of ethically at their own expense.

Drum reconditioning will allow you to gain a competitive advantage by creating a closed loop process. By implementing a circular supply chain not only will you save costs of repurchasing new drums but will demonstrate to your customers, that your company cares about our planet.

That is why the industry is changing. Many suppliers are choosing to take this problem away from their customers by simply utilising their empty vans to return the spent containers back to their facility, washing and processing them with our machinery and returning them in perfect condition ready to be reused.

Not only does this reduce the operational costs for your customers, increase your competitiveness in the marketplace, but it also reduces your running costs.

The global economy is reliant on the fast and inexpensive transportation of chemicals and liquids across road, rail and shipping networks. Most industrial processes require chemicals or additives to be delivered on a regular basis, requiring a huge stock of containers across the supply chain.

But what happens to all the spent containers?

Drum reconditioning is nothing new, back in the days of wooden barrels and ships this was an incredibly skilled job requiring large investments in capital and labour. Thankfully, we have developed and so have the materials we use to transport our products.

Blow moulded, HDPE barrels or drums have become the new norm with millions in circulation across the planet. Cheap to produce, lightweight and durable it is no surprise we do not see wooden barrels on lorries these days. Unfortunately, the cost-effectiveness of HDPE barrels has led to its own issues, namely the 100,000t of plastic scrap produced once these containers have been emptied.

Changes in taxation and policy across the western world have drastically increased the deposal price for companies using process chemicals, driving the necessity for a closed-loop process.

Contact Rotajet

We aim to get back to any enquiry within 12 hours, so please contact us if you are interested in a specific machine or would like to discuss an individual cleaning application. Our friendly team are happy to help via email at info@rotajet.co.uk or by phone on +44 (0) 1924 271446