Drum Crushers

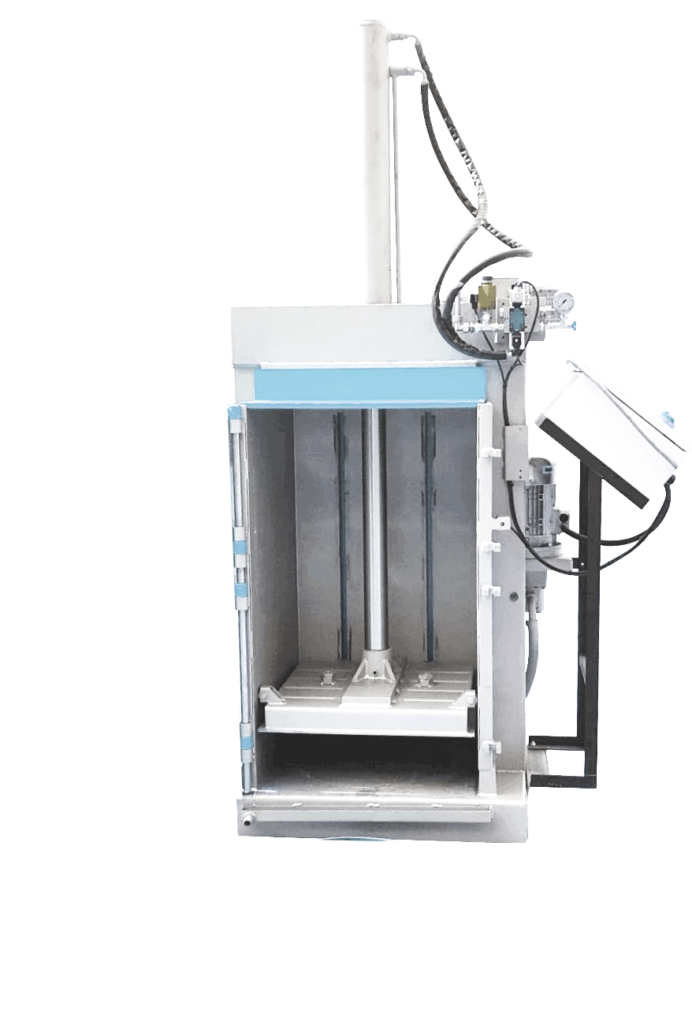

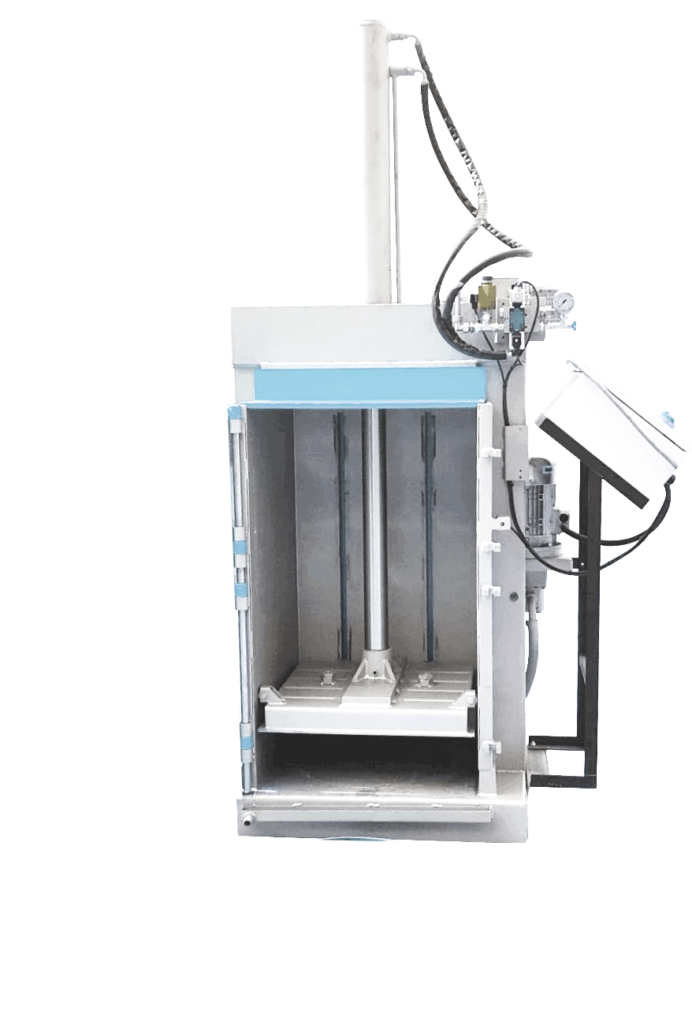

Rotajet’s RJ-DSC drum crushers are a fast and reliable way of increasing the mass density of your scrap drums when sending them for safe disposal. This machine has been designed to hold a 210L drum, however is suitable for crushing cans and canisters of smaller dimensions.

Rotajet drum crushers are used all over the world to crush drums, buckets and pails. The system uses a hydraulic ram to crush containers down to a maximum height of 200mm. The ram is fitted with penetration lugs to perforate the container and allow any trapped gases to escape.

Many containers are used to transport and store hazardous chemicals. Depending on contaminates that are present, it may be necessary to use an ATEX-certified machine to ensure the safety of your operator.

Discharge of fluid is phased into a channel leading to a 20mm diameter pipe outlet, 200mm long at the front of the base plate. Rotajet drum crushers crush the drums down to approx. 100mm to 160mm; ideal for skips or transportation.

We use only high-quality components to ensure the RJ-DSC are built to handle the highest demands in the industry. We make sure that your operators are protected with all the safety features required to use and maintain the machine, including; safety interlocks and an emergency stop circuit.

Our range of drum crushers includes pneumatic models with a 9 or 15 tonne pressing force. Each model can be manufactured to ATEX standards for use in a flammable atmosphere. We also manufacture a combined drum washer and crusher for those interested in washing drums for safe disposal.

Read our article on the Plastic Packaging Tax to find out how your company can prepare for the new regulations.

Drum Washers

Pressure Testers

Drum Crushers

Full Systems

Contact Rotajet

We aim to get back to any enquiry within 12 hours, so please contact us if you are interested in a specific machine or would like to discuss an individual cleaning application. Our friendly team are happy to help via email at info@rotajet.co.uk or by phone on +44 (0) 1924 271446